Programme technique 2025

Voici le résumé des présentations et les biographies des conférenciers. Les présentations peuvent être français ou en anglais. La langue du titre et du résumé indique la langue de chaque présentation.

TÉLÉCHARGER LE PROGRAMME DE LA CONFÉRENCE TECHNIQUE ANNUELLE 2025 DE L’ACVM

From Vibration to Insight: Advancing Predictive Maintenance with AI and Data-Driven Diagnostics

As industrial systems grow in complexity and interdependence, traditional maintenance strategies fall short in meeting the demands for resilience, cost-efficiency, and real-time decision-making. This plenary presentation explores cutting-edge predictive maintenance strategies that harness deep learning, remaining useful lifetime (RUL) prediction, and optimization to improve reliability and resilience in industrial systems.

We explore how advanced models, such as Bi-LSTM neural networks and probabilistic RUL estimators, transform raw vibration signals into actionable prognostics for rotating machinery. Examples will demonstrate how these models enable early fault detection, optimized maintenance timing, and reduced unplanned downtime. Key insights include: i) integration of vibration data into deep learning architectures for accurate fault prediction; ii) use of uncertainty-aware RUL prediction to guide risk-informed maintenance decisions; iii) scalable optimization models that turn health predictions into cost-effective maintenance schedules for fleets and complex systems.

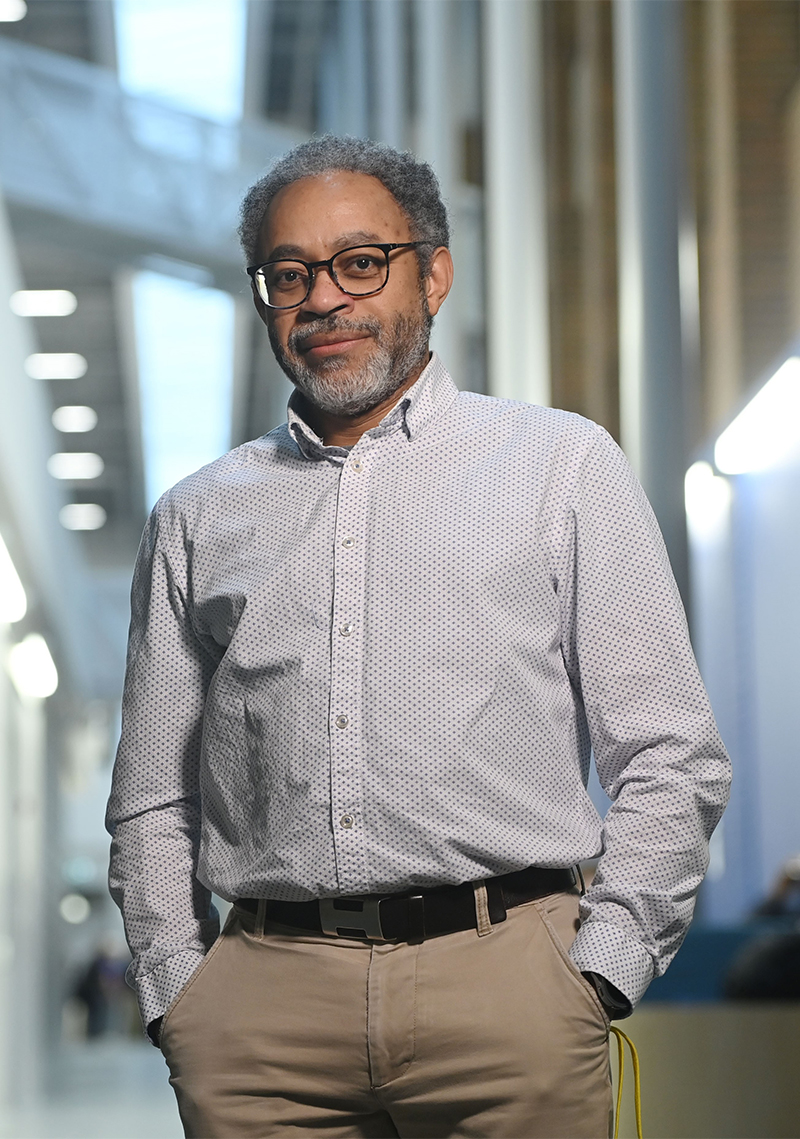

Claver Diallo, Dalhousie University, Keynote Speaker/Conférencier invité

Claver Diallo, Ph.D., P.Eng., is a Professor in the Department of Industrial Engineering at Dalhousie University in Halifax, Nova Scotia, where he has taught since 2007. His research focuses on performance optimization in production and service systems, with expertise in maintenance engineering and management, reliability and availability engineering, remanufacturing, project scheduling, and sustainable closed-loop supply chain design. Dr. Diallo’s recent work explores the integration of reliability engineering and predictive maintenance with smart production and hyperconnected logistics systems within the Industry 4.0/5.0 paradigm. He holds a Ph.D. and M.A.Sc. in Industrial Engineering, as well as a B.Eng. in Mechanical Engineering, from Laval University (Québec). He is a member of the Institute of Industrial and Systems Engineering (IISE), Engineers Nova Scotia, Canadian Operational Research Society (CORS), and International Federation of Automation and Control (IFAC) Technical Committee 5.2.

Claver Diallo, Ph.D., P.Eng., is a Professor in the Department of Industrial Engineering at Dalhousie University in Halifax, Nova Scotia, where he has taught since 2007. His research focuses on performance optimization in production and service systems, with expertise in maintenance engineering and management, reliability and availability engineering, remanufacturing, project scheduling, and sustainable closed-loop supply chain design. Dr. Diallo’s recent work explores the integration of reliability engineering and predictive maintenance with smart production and hyperconnected logistics systems within the Industry 4.0/5.0 paradigm. He holds a Ph.D. and M.A.Sc. in Industrial Engineering, as well as a B.Eng. in Mechanical Engineering, from Laval University (Québec). He is a member of the Institute of Industrial and Systems Engineering (IISE), Engineers Nova Scotia, Canadian Operational Research Society (CORS), and International Federation of Automation and Control (IFAC) Technical Committee 5.2.

Claver Diallo, PhD, ing., est professeur au Département de génie industriel de l’Université Dalhousie à Halifax (Nouvelle-Écosse), où il enseigne depuis 2007. Ses travaux de recherche portent sur l’optimisation de la performance des systèmes de production et de service, avec une expertise en ingénierie et gestion de la maintenance, ingénierie de la fiabilité et de la disponibilité, remanufacturage, ordonnancement de projets et conception de chaînes d’approvisionnement durables. Ses travaux récents explorent l’intégration de l’ingénierie de la fiabilité et de la maintenance prédictive à la production intelligente et aux systèmes logistiques hyperconnectés dans le cadre du paradigme de l’industrie 4.0/5.0. Il est titulaire d’un doctorat, d’une maîtrise et d’un baccalauréat en génie mécanique, de l’Université Laval (Québec). Il est membre de l’Institute of Industrial and Systems Engineering, Engineers Nova Scotia, Société canadienne de recherche opérationnelle (SCRO) et de la Fédération internationale de l’automatisation et du contrôle (IFAC-TC 5.2).

L’avenir de la surveillance de l’état de santé des actifs dans un monde en pénurie de main-d’œuvre

Les organisations investissent depuis des années dans les technologies et la formation afin de mettre en œuvre et de maintenir des programmes de surveillance de la santé des actifs. Cependant, la disponibilité des ressources qualifiées pour soutenir ces activités essentielles diminue. En conséquence, les organisations explorent diverses solutions pour combler cet écart et accomplir davantage avec moins de ressources. Dans ce contexte, nous examinerons différentes possibilités pour l’avenir de la surveillance de la santé des actifs, telles que le suivi à distance, l’intégration de l’intelligence artificielle et de l’apprentissage automatique, la surveillance en ligne comparativement à la collecte manuelle des données, et bien plus encore. Nous évaluerons également le retour sur investissement de ces différentes options.

The future of Condition Monitoring and Reliability in a world with skill shortage

Asset-intensive organizations have been investing in technologies and training for years to implement and maintain robust condition monitoring programs, yielding significant benefits. However, the availability of skilled resources to sustain these critical activities is diminishing. As a result, organizations are exploring various solutions to bridge this gap and accomplish more with fewer resources. In this context, we will explore different possibilities for the future of condition-based monitoring (CBM), such as remote CBM, AI and ML integration, online CBM vs.versus route-based monitoring, and more. We will also assess the return on investment for these options.

Alain Pellegrino, Reliability Solutions, Keynote Speaker/Conférencier invité

Alain Pellegrino est un professionnel certifié en maintenance et fiabilité (CMRP) fort de plus de 20 ans d’expérience comme consultant en fiabilité. Il est président de Reliability Solutions LP, à Pensacola, en Floride. Il dirige et gère une équipe de 50 consultants techniques spécialisés en maintenance de précision, inspections opérateurs et ingénierie de fiabilité. Leur mission est d’aider les clients à atteindre des résultats profitable grâce à l’excellence en matière de fabrication fiable.

Alain Pellegrino est un professionnel certifié en maintenance et fiabilité (CMRP) fort de plus de 20 ans d’expérience comme consultant en fiabilité. Il est président de Reliability Solutions LP, à Pensacola, en Floride. Il dirige et gère une équipe de 50 consultants techniques spécialisés en maintenance de précision, inspections opérateurs et ingénierie de fiabilité. Leur mission est d’aider les clients à atteindre des résultats profitable grâce à l’excellence en matière de fabrication fiable.

Alain Pellegrino is a Certified Maintenance and Reliability Professional (CMRP), with more than 20 years’ experience in Reliability consulting. He is the President of Reliability Solutions LP, in Pensacola Florida. Leading and managing a team of 50 technical consultants, specialized

in precision maintenance, Operator care and reliability engineering. Their mission is to assist clients in achieving Profitable Results® through excellence in Reliable Manufacturing®.

Identifying and Solving Resonance, A Case Study – DPS Pump

This case study follows the entire process, from initial discovery to the final solution, of identifying and solving a resonance problem involving a dry pit submersible pump. The presentation begins with how the problem was presented to us along with the client’s frustration at not having a solution that would work, even though some had been tried. We show how we developed a test plan to identify and confirm the problem using multiple tests including bump testing, runup and coast down testing, and phase analysis using operating deflection shapes. We then present the test results data using a variety of graphics including data plots, photographs, and animations. Relevant details of the AINSI / Hydraulic Institute 9.6.4 specification and the OEM vibration specification are reviewed and discussed. There is also some explanation of the hydraulic forces generated by centrifugal pumps and the vibration that results. Finally, the options available to solve resonance in this circumstance are discussed. Some are not possible, and some are not acceptable to the client. Given these conditions, a solution is determined and implemented. The solution is presented with more photographs of how it was tested and finally implemented. Many of the original tests were reperformed on the solution to substantiate the effectiveness of the solution.

Grant Akitt, PDM Technologies

Grant Akitt is a Mechanical Engineer specializing in vibration analysis on rotating equipment and their structures. With over 30 years of experience in the industry, he is accomplished in vibration measurement and analysis, transient data analysis, operational deflection shape testing / phase analysis, and dynamic balancing.

Grant began his career in 1991 as a Condition Monitoring Specialist for SKF Canada Limited in Scarborough, Ontario. He then worked for SKF Condition Monitoring, based in Houston, Texas, for 3 years as an Industry Specialist in both the Metals and Mining group and the Pulp and Paper group. Following this was a variety of positions working as a Team Lead in the Predictive Maintenance field for service companies operating in Southern Ontario, after which he acquired PDM Technologies in 2007. Grant is a licensed Professional Engineer and a certified Category III vibration analyst since 2017.

Grant Akitt est un ingénieur en mécanique, spécialisé dans l’analyse des vibrations des équipements rotatifs et de leurs structures. Fort de plus de 30 ans d’expérience dans l’industrie, il est reconnu pour ses compétences en mesure et analyse des vibrations, en analyse de données transitoires, en essais de déformation en fonctionnement. en analyse de phase et en équilibrage dynamique. Grant a débuté sa carrière en 1991 comme spécialiste en surveillance conditionnelle chez SKF Canada Limitée à Scarborough, en Ontario. Il a ensuite travaillé pendant trois ans chez SKF Condition Monitoring, à Houston, au Texas, comme spécialiste industriel au sein des groupes Métaux et mines et Pâtes et papiers. Il a ensuite occupé divers postes de chef d’équipe en maintenance prédictive pour des entreprises de services opérant dans le sud de l’Ontario, avant d’acquérir PDM Technologies en 2007. Grant est un ingénieur agréé et un analyste en vibrations certifié de catégorie III depuis 2017.

Optimising resource-constrained fleet selective maintenance with asynchronous maintenance breaks

This research offers a novel and significant extension of the Fleet Selective Maintenance Problem (FSMP) by considering asynchronous maintenance breaks and resource-constrained maintenance planning. This constitutes a significant shift from the conventional focus on synchronous breaks for the FSMP formulated to plan maintenance for fleets of mission-critical systems. This paper establishes a theoretical link between the Selective Maintenance Problem (SMP) and the Resource Constrained Project Scheduling Problem (RCPSP). The proposed FSMP formulation for asynchronous breaks is more general and versatile in adapting to a broad spectrum of operational constraints and resource scarcities. Numerical experiments are conducted that highlights the trade-offs between the timing and quality levels of maintenance activities and the consumption of resources that maintenance planners can make to obtain the best system performance for the budget and maintenance windows available.

Alireza Amjadian, University of Dalhousie

Alireza Amjadian is currently pursuing a Ph.D. degree from the Department of Industrial Engineering at Dalhousie University, Halifax, Nova Scotia, Canada. He holds a Master of Applied Science degree and a Bachelor’s degree in Industrial Engineering from Kharazmi University, Iran. His current research interests include remanufacturing, pricing and revenue management, supply chain, and intelligent maintenance operations.

Alireza Amjadian poursuit actuellement un doctorat au département de génie industriel de l’Université Dalhousie, à Halifax, Nouvelle-Écosse, Canada. Il est titulaire d’une maîtrise ès sciences appliquées et d’un baccalauréat en génie industriel de l’Université Kharazmi, en Iran. Ses intérêts de recherche actuels portent sur le remanufacturage, la tarification et la gestion des revenus, la chaîne d’approvisionnement et les opérations de maintenance intelligente.

Using Bi-LSTMs for Diagnostics and Prognostics in Data-Driven Maintenance Planning

Modern industries dependent on reliable asset operation under constrained resources employ intelligent maintenance methods to maximize efficiency. However, classical maintenance methods rely on assumed lifetime distributions and suffer from estimation errors and computational complexity. The advent of Industry 4.0 has increased the use of sensors for monitoring systems, while deep learning (DL) models have allowed for accurate system health predictions, enabling data-driven maintenance planning. Often, sensor data comes in a time-series format, making recurrent neural networks (RNNs) particularly suitable for data analysis. A subset of RNNs that have shown a lot of promise in diagnostic and prognostic tasks is bidirectional long short-term memory models (Bi-LSTMs). However, past literature using Bi-LSTMs in these tasks has not fully tested the architecture’s limits, either by limiting the scope of data used or by failing to explicitly tune hyperparameters, instead augmenting with additional DL architecture without justification. Hence, this paper tests a minimalist Bi-LSTM model with the Case Western Reserve University dataset to assess its ability to perform multi-faceted bearing fault diagnoses. The model has seven hyperparameters explicitly tuned prior to testing and has performance on par with many state-of-the-art models. With the strength of Bi-LSTM architecture demonstrated, a hybrid Bi-LSTM model is developed to generate RUL predictions from the NASA C-MAPSS dataset and a separate filter dataset. Using Monte Carlo dropout, empirical reliability functions are generated for the optimization of the selective maintenance problem (SMP). The proposed framework is used to plan maintenance for a mission-oriented series k-out-of-n:G system. Numerical experiments compare the framework’s performance against prior SMP methods and highlight its strengths. When minimizing cost, maintenance plans frequently result in mission survival while avoiding unnecessary repairs. The proposed method is usable in large-scale, complex scenarios and finds exact solutions while avoiding the need for computationally-intensive parametric reliability functions.

Alexandros Noussis

Alexandros Noussis is a graduate student studying industrial engineering at Dalhousie University, based in Halifax, Nova Scotia. He gained his Bachelor of Industrial Engineering in 2023 and Master of Applied Science in 2025, both at Dalhousie. His MASc researched focused on condition-based, intelligent maintenance for marine renewable energy (MRE) systems while incorporating machine learning. He is currently pursuing his PhD on intelligent maintenance planning for MRE production assets. His work in MRE has expanded to include data collection frameworks and digital twin use. He is a recipient of the 2023 Natural Sciences and Engineering Research Council of Canada (NSERC) Canada Graduate Scholarship for Master’s students, as well as a recipient of the 2025 Postgraduate Scholarship for Doctoral students from NSERC.

Alexandros Noussis est un étudiant diplômé en génie industriel de l’Université Dalhousie, située à Halifax, en Nouvelle-Écosse. Il a obtenu son baccalauréat en génie industriel en 2023 et sa maîtrise en sciences appliquées en 2025 de Dalhousie. Ses recherches de maîtrise en sciences appliquées portaient sur la maintenance intelligente et conditionnelle des systèmes d’énergie marine renouvelable (EMR) en intégrant l’apprentissage automatique. Il poursuit actuellement un doctorat sur la maintenance intelligente des systèmes de production d’énergie renouvelable. Ses travaux en EMR se sont élargis pour inclure la collecte de données massives et l’utilisation des jumeaux numériques. Il est lauréat de la bourse d’études supérieures du Canada pour les étudiants à la maîtrise du Conseil de recherches en sciences naturelles et en génie du Canada (CRSNG) en 2023, ainsi que de la bourse d’études supérieures pour les étudiants au doctorat du CRSNG en 2025.

Optimizing budget allocation for multimission selective maintenance planning

Mission-critical systems in sectors such as aerospace, defence, transportation, petrochemistry, and power generation require high reliability to prevent failures causing major economic losses, environmental damages, and safety risks. For such systems, solving the selective maintenance problem (SMP) yields optimal maintenance planning decisions during scheduled breaks. Its extension, the multi-mission SMP (MMSMP),focuses on optimizing component maintenance, maintenance levels, and repairperson assignments over multiple consecutive missions interspersed with maintenance breaks. While recent advances integrate predictive,resource-constrained, and fleet-wide strategies, they rely on the unrealistic assumption of fixed budgets, ignoring the reality of fluctuating and tight financial constraints faced by planners. This study investigates how different maintenance budget allocations across missions affect system performance. Using a two-phase de-composition model and binary integer programming, it explores various budget distribution strategies: uniform,linearly increasing, and inverted-V. The goal is to determine how allocating resources differently across mis-sions can enhance asset reliability within fixed budget limits. The findings aim to guide maintenance plannersin making budget decisions to improve overall system reliability while balancing resource constraints.

Farzad Falahaty, University of Dalhousie

Farzad Falahaty is currently pursuing a MASc degree from the Department of Industrial Engineering at Dalhousie University, Halifax, Nova Scotia, Canada. He holds a Master of Management of Technology degree from Iran University of Science and Technology (IUST) and a Bachelor’s degree in Industrial Engineering from IAU South Tehran Branch Faculty of Engineering, Iran. His current research interests include Maintenance Engineering and Management, Reliability and Availability Engineering, and Quality Control & Reliability.

Farzad Falahaty prépare actuellement une maîtrise en sciences au département de génie industriel de l’Université Dalhousie, à Halifax, en Nouvelle-Écosse, au Canada. Il est titulaire d’une maîtrise en gestion des technologies de l’Université iranienne des sciences et technologies (IUST) et d’une licence en génie industriel de la faculté de génie de l’antenne sud de Téhéran de l’IAU, en Iran. Ses recherches portent actuellement sur l’ingénierie et la gestion de la maintenance, l’ingénierie de la fiabilité et de la disponibilité, ainsi que le contrôle qualité et la fiabilité.

Leveraging AI and Machine Learning for Diagnostics at Scale

What if your reliability team could trust every insight from their condition monitoring system? What if they could use their time to be focused on more complex issues, knowing that AI and ML are keeping a watch out for their assets, flagging for attention only when there is an issue that needs to be addressed? AI/ML for machine condition monitoring has come of age and is learning and scaling at a rapid pace. AI/ML exists in many forms, and each has a specific application where it can be used. It can be an extraordinary tool to add to your toolbox, but it requires careful consideration. We’ll be looking at how AI/ML can be applied for machine condition monitoring. Behaviour models can be created for generic non-critical rolling element bearing machines using ML, however do we model one machine based on its lone history, or do we model many similar machines and build a broader picture of how a particular type of machine is expected to behave? There are pros and cons to either approach as well the type of AI we use to tackle the problem. We’ll also look at the kinds of information we can extract from a simple waveform sample and how adding in other information such as magnetic flux and temperature can help to build a more accurate picture of machine behaviour.

Keehan Dowd, Baker Hugues

With a formal background in Instrumentation Engineering, Keehan Dowd is passionate about measuring and understanding the behaviour of complex systems. He started with Bently Nevada as a Systems Integrator, helping import and export machine data to and from condition monitoring and plant historian software. Over his 28 years at Bently Nevada, he has learned that machines speak to us through vibration, and he has learned to understand machine behaviour through vibration analytics. There are also significant benefits integrating data beyond just vibration with process information to help build a contextual and more wholistic picture of machine behaviour. Bently Nevada is now codifying its 60 years of condition monitoring and machine behaviour expertise by leveraging new AI and Machine Learning techniques to produce truly remarkable outcomes and Keehan was been lucky enough to work at the coal face of this exciting technology.

Fort d’une formation en ingénierie de l’instrumentation, Keehan Dowd est passionné par la mesure et la compréhension du comportement des systèmes complexes. Il a débuté chez Bently Nevada en tant qu’intégrateur de systèmes, participant à l’importation et à l’exportation de données machines vers et depuis des logiciels de surveillance d’état et d’historisation d’usine. Au cours de ses 28 années chez Bently Nevada, il a appris que les machines nous parlent par le biais des vibrations et qu’il comprenait leur comportement grâce à l’analyse vibratoire. L’intégration de données autres que les vibrations aux informations de processus présente également des avantages considérables pour permettre d’obtenir une vision contextuelle et plus globale du comportement des machines. Bently Nevada concrétise aujourd’hui ses 60 années d’expertise en surveillance d’état et en comportement des machines en exploitant les nouvelles techniques d’IA et d’apprentissage automatique pour produire des résultats remarquables. Keehan a eu la chance de travailler au cœur de cette technologie prometteuse.

Process Optimization Woodchippers

Extending its range of process optimization solutions, SPM Instrument now launches knife wear monitoring for woodchippers. The knife system is the heart of the chipper, and its effectiveness in producing premium-quality wood chips impacts the entire downstream process. Profitable pulp production begins with high-quality, even-sized wood chips. In pulp mills, all the raw material passes through the woodchipper, and its ability to deliver top-grade chips is paramount to digester or refiner performance, pulp quality, raw material yield, and product quality.

The critical role of knife condition in wood chip quality

In the chemical and mechanical pulping process, the size distribution of wood chips is crucial for a smooth process in subsequent stages. Variations in chip thickness lead to uneven penetration of cooking liquors and, as a result, less efficient impregnation. In addition to wood quality, the chipper knife system has the greatest impact on final chip quality. Keeping the woodchipper running with knives in good condition is the most effective and cost-efficient way to maximize pulp yield and quality. Dull or damaged knives typically result in increased and inconsistent chip sizes, leading to lower-quality pulp. Contaminants such as rocks can damage the knives, particularly during winter. Blunt blades also cause greater impact forces on the machine. However, the ideal time to replace the knives is not easily identifiable, and this assessment often relies on operator experience.

Informed decisions, better results: boosting quality and minimizing waste

SPM’s knife wear monitoring solution provides insights into the condition of chipper knives and offers decision support on managing chipper knife replacement. In a web-based dashboard, clear and easy-to-understand graphs indicate whether a knife is damaged, becoming dull, detached, or missing from the knife holder:

Woodchipper dashboard

Benefits of monitoring knife sharpness and identifying situations where one or more knives deviate from the others include:

-

- production of wood chips with a more uniform size and thickness

- minimized rejects and maximized accepts

- higher raw material yields

- higher digester throughput – examples show increases in the order of 10%

- condition-based knife replacement

Karl-Johan Ericsson, Maintenance Manager at Swedish pulp mill Aspa Pulp: “The system is very stable, and the results are reliable. It tells the truth about the status of the process and the knife condition in real time. The web app shows customized graphs on a screen in the control room, which is super easy to understand and very helpful to the operators.”

Knife wear monitoring with innovative HD technology

Woodchippers are subject to extensive vibrations and impacts arising from logs hitting the chipper disc, making them a “noisy” environment for data acquisition. The random infeed of logs is a further challenge. SPM’s online system Intellinova Parallel EN and patented HD technology algorithms handle these factors with exceptional results. Using the same equipment, chipper knife monitoring can be cost-effectively combined with monitoring the mechanical and lubrication condition of the chipper’s rotating parts, such as main bearings, gearboxes, viscous couplings, and motors.

Ron Kittle, SPM Instrument North America

Ron Kittle is Vice President of Technical Sales & Support for SPM Instrument North America, a global leader in condition monitoring that exclusively develops and markets all the advanced technologies to measure, analyze and present condition data from complex machinery. Ron has over 20 years of experience in the maintenance and reliability fields, primarily focusing on condition monitoring products related to vibration analysis across many industries. Ron has extensive experience in wireless and on-line condition monitoring systems, most recent notable work in the wind energy and mining industries. Ron’s career started in the US Army where he spent time as a Combat Vehicle Mechanic. Other early career experiences include oil analysis on high voltage transformers and work in the power generation plants where he began focusing on predictive maintenance techniques. Ron has studied electronics at the National Institute of Electronics, holding many certifications in predictive maintenance technologies such as thermography and vibration analysis.

Ron Kittle est vice-président des ventes et du support technique chez SPM Instrument North America, leader mondial de la surveillance d’état qui développe et commercialise en exclusivité des technologies de pointe pour mesurer, analyser et présenter les données d’état de machines complexes. Ron possède plus de 20 ans d’expérience dans les domaines de la maintenance et de la fiabilité, principalement axée sur les produits de surveillance d’état liés à l’analyse vibratoire dans de nombreux secteurs. Il possède une vaste expérience des systèmes de surveillance d’état sans fil et en ligne, notamment dans les secteurs de l’énergie éolienne et minière. Il a débuté sa carrière dans l’armée américaine, où il a été mécanicien de véhicules de combat. Il a également travaillé en début de carrière dans l’analyse d’huile sur des transformateurs haute tension et dans des centrales électriques, où il a commencé à se concentrer sur les techniques de maintenance prédictive. Ron a étudié l’électronique au National Institute of Electronics et est titulaire de nombreuses certifications en technologies de maintenance prédictive, telles que la thermographie et l’analyse vibratoire.

Ultrasound case histories of mechanical system defects

This presentation will provide examples of airborne and structural mechanical faults,as well as examples of lubrication and electrical defects.

Études de cas en ultrasons de défauts de systèmes mécaniques

Cette présentation fournira des exemples de défauts mécaniques aériens et structurels, de même que des exemples de défauts de lubrification et électriques.

Gilles Lanthier, SDT Ultrasound Solutions

Mr. Gilles Lanthier is the SDT Ultrasound Solutions District Manager for Quebec and Maritimes. Mr. Lanthier is a CMVA CAT III Vibration Analyst, a Level 2 Ultrasound Specialist, and a Certified Reliability Leader with more than 25 years experience in the field.

M. Gilles Lanthier est directeur régional de SDT Ultrasound Solutions pour le Québec et les Maritimes. M. Lanthier est analyste en vibrations ACVM CAT III, spécialiste en ultrasons de niveau 2 et leader certifié en fiabilité, fort de plus de 25 ans d’expérience dans le domaine.

Managing Installed Wireless Devices in Industrial Environments

As industry increasingly adopts wireless technologies to enhance vibration monitoring the need for effective management of these devices becomes more important. In this presentation we will explore best practices for overseeing installed wireless devices ensuring they remain reliable sources of information. Key focus areas include establishing and maintaining an up-to-date register of all wireless devices, implementing routine inspection protocols, and integrating wireless device checks into existing maintenance interventions. By adopting a structured approach to wireless device management facilities can minimize downtime and support long-term digital transformation initiatives.

Sarah McGuire, Atlantic Controls

Sarah McGuire is a CMVA Category II vibration analysist who works as a reliability specialist for Atlantic Controls. She is a mechanical engineer who graduated from Memorial University of Newfoundland and Labrador. She has experience working with different industries including power generation, oil & gas, mining, and pulp & paper. Her career in reliability has allowed her to touch on many aspects of vibration and acoustics including route collection, machinery diagnostics, training and regulatory compliance.

Sarah McGuire, analyste certifiée catégorie II de l’ACVM, dans le département de fiabilité chez Atlantic Controls. Ingénieure mécanique diplômée de la Memorial University of Newfoundland and Labrador, Sarah a de l’expérience dans plusieurs domaines industriels incluant énergétique, pétrochimie, minier, et pâtes et papier. Sa carrière en fiabilité lui a permis d’oeuvrer dans différents domaines d’activité de la vibration et de l’acoustique, tels que la collecte de données de route vibratoire, diagnostics de machine, formation et conformité réglementaire.

The Implementation and Benefits of an APM program

This presentation will cover the benefits and return on investment of the implementation of an Asset Performance Management system. An APM system is a support program to the typical CMMS and siloed condition monitoring program like vibration, thermography and Ultrasound. This APM program pulls all data and reports together in one dashboard to help understand the asset health of an entire facility or business in one view. I will include all the implementation details and challenges involved in this type of APM program. This APM program includes the tools required to build a risk-based maintenance strategy that includes operator basic care, failure finding tasks, lubrication task information and all the condition monitoring tactics. This program is also supported with a digital handheld for all field inspection details.

Charles Scott, Irving Consumer Products

Charles Scott works at Irving Consumer Products since 1994. The majority of this time included working at the Irving Tissue Dieppe Converting Facility in a variety of maintenance and reliability positions, including Red Seal Millwright, Vibration Analyst, Lubrication Specialist and current role as Maintenance Coordinator. Charles has also spent time between 2018 and 2021 working with the Macon, Georgia Converting Facility green field expansion responsible for the development of the maintenance and reliability programs. Charles detains a CMVA CAT III Vibration Certification and a Maintenance Management Professional Certification through PEMAC.

Charles Scott travaille chez Irving Consumer Products depuis 1994. Il a principalement travaillé à l’usine de transformation Irving Tissue de Dieppe, où il a occupé divers postes liés à la maintenance et à la fiabilité, notamment comme mécanicien Red Seal, analyste des vibrations, spécialiste en lubrification et, actuellement, comme coordonnateur de la maintenance. De 2018 à 2021, Charles a également collaboré à l’agrandissement de l’usine de transformation de Macon, en Géorgie, où il a été responsable du développement des programmes de maintenance et de fiabilité. Il est titulaire d’une certification ACVM CAT III en vibrations et d’une certification professionnelle en gestion de la maintenance délivrée par PEMAC.

VFD related motor faults

This presentation covers both winding related faults and bearing failures in AC motors caused by modern variable frequency drives, as well as mitigation practice to help prevent failures.

Joe Koncovy, Source Atlantic

Joe Koncovy graduated from Technical University with a degree in Electrical Engineering. He counts more than 35 years experience in repair of Industrial Rotating Equipment. He currently manages the Source Atlantic Industrial repair facility and in the past, worked for Westinghouse, Siemens and Nova Scotia Power.

Joe Koncovy est titulaire d’un diplôme en génie électrique de l’Université technique. Il possède plus de 35 ans d’expérience dans la réparation d’équipements rotatifs industriels. Il dirige actuellement le centre de réparation industriel de Source Atlantic et a travaillé pour Westinghouse, Siemens et Nova Scotia Power.

Reciprocating compressors analysis

In this presentation, Jordan Wood will speak on reciprocating Compressor Basics, components of a reciprocating compressor, sensors and equipment used for analysis, reciprocating compressor analysis and offline and online condition monitoring.

Jordan Wood, Irving Oil

Jordan Wood graduated from the Mechanical Engineering Technology program at NBCC in 2011, joining the Reliability Engineering Team at the Irving Oil refinery thereafter. During his first 11 years with Irving Oil, he was primarily involved in vibration monitoring, reciprocating compressor analysis, oil analysis and major equipment overhauls during turnarounds. Over the past 3 years he has been working as a rotating equipment technologist dealing with day-to-day maintenance for all the rotating equipment that comes through the shop, with continued involvement in the condition monitoring program.

Jordan Wood a obtenu son diplôme de technologie du génie mécanique au NBCC en 2011 et a ensuite rejoint l’équipe d’ingénierie de la fiabilité de la raffinerie d’Irving Oil. Durant ses 11 premières années chez Irving Oil, il a principalement été impliqué dans la surveillance des vibrations, l’analyse des compresseurs alternatifs, l’analyse des huiles et les révisions majeures des équipements lors des arrêts techniques. Ces trois dernières années, il a travaillé comme technologue en équipements rotatifs, s’occupant de la maintenance quotidienne de tous les équipements rotatifs entrant dans l’atelier, tout en participant activement au programme de surveillance de l’état.

Towards Intelligent Bearing Health Monitoring: Techniques and Applications

Bearings are essential components in rotating machinery, and their failure can lead to significant downtime and economic loss. This presentation focuses on intelligent techniques for real-time bearing health monitoring that are robust, effective, and suitable for practical industrial applications. Advanced signal processing methods are used to extract meaningful features from vibration and sensor data, while machine learning algorithms enable accurate fault detection, diagnosis, and prediction. The system integrates hardware and software solutions to facilitate online monitoring, data acquisition, and alarm management, reducing the need for manual intervention by engineers. Case studies demonstrate the performance of these methods in real machinery, highlighting their reliability, scalability, and applicability to predictive maintenance. Future directions for enhancing monitoring systems and deploying autonomous solutions in industrial settings are also discussed.

Larry Liang, University of Manitoba

Xihui (Larry) Liang is an Associate Professor in the Department of Mechanical Engineering at the University of Manitoba, Winnipeg, Canada. His research spans nonlinear dynamics, intelligent machinery health monitoring, predictive maintenance, and non-destructive testing, with a particular emphasis on vibration-based diagnostic techniques and the development of smart bearings capable of self-powering and self-sensing. Over the years, he has attracted significant research funding and earned international recognition for his contributions, including the Terry G. Falconer Memorial Rh Institute Foundation Emerging Researcher Award and the UM/UMFA Research Merit Award. Dr. Liang is also active in the academic community, taking on editorial responsibilities such as Associate Editor of IEEE Transactions on Industrial Informatics and serving on the Editorial Board of Measurement Science and Technology. In addition, he has contributed to the organization of several international conferences in roles including Program Chair and committee member, while continuing to advance innovative methods in machinery monitoring and reliability engineering.

Xihui (Larry) Liang est professeur agrégé au département de Génie mécanique de l’Université du Manitoba, à Winnipeg, au Canada. Ses recherches portent sur la dynamique non linéaire, la surveillance intelligente de l’état des machines, la maintenance prédictive et les techniques d’essais non destructifs, avec un accent particulier sur les méthodes de diagnostic vibratoire et le développement de roulements intelligents capables d’auto-alimentation et d’auto-surveillance. Au fil des années, il a obtenu d’importants financements de recherche et a acquis une reconnaissance internationale pour ses contributions, récompensées notamment par le Terry G. Falconer Memorial Rh Institute Foundation Emerging Researcher Award et le UM/UMFA Research Merit Award. Le Dr Liang participe activement à la communauté scientifique à travers divers rôles éditoriaux, tels qu’éditeur associé de l’IEEE Transactions on Industrial Informatics et membre du comité éditorial de Measurement Science and Technology. Il a également joué un rôle de premier plan dans plusieurs conférences internationales en tant que président de programme et membre de comité, tout en poursuivant le développement de méthodes innovantes en surveillance des machines et en ingénierie de la fiabilité.

Les paliers hydrodynamiques

Pour beaucoup d’analystes en vibration, les paliers hydrodynamiques communément appelés Babbit ou paliers lisses sont très souvent une bête noire, car très difficiles à diagnostiquer à l’aide d’un analyseur de vibration conventionnel et d’un accéléromètre. Quoique ce type de palier soit présent dans différentes machines depuis près de 100 ans, ils sont toujours encore en utilisation dans nos machines modernes. Dans cette présentation, je tenterai d’en expliquer le principe de fonctionnement. M. Lavallée s’attardera particulièrement à leurs principales causes de défaillances et à la façon de les diagnostiquer. Il sera aussi beaucoup question de mesure de vibration sur ces paliers et de représentation graphique. La présentation sera accompagnée de nombreuses photos et tableaux permettant d’en améliorer la compréhension.

Louis Lavallée, Analyste CAT III retraité

Louis Lavallée est un ingénieur membre de l’OIQ ayant cumulé plus de 30 ans d’expérience dans le domaine des vibrations de machineries. Il a développé au fil des années une grande expertise dans le domaine des vibrations de moteurs électriques chez Delom Services de Montréal. Il a aussi été très actif au sein de l’ACVM autant au niveau du chapitre du Québec que comme président national. Aujourd’hui à la retraite, il continue de partager son savoir en offrant des formations en industrie.

Louis Lavallée is an engineer member of the OIQ with over 30 years of experience in the machinery vibrations analysis. Over the years, he has developed extensive expertise in electric motor vibrations analysis at Delom Services in Montreal. He has also been very active within the CMVA, both at the Quebec chapter level and as national president. Now retired, he continues to share his knowledge by offering industry training.

Factory Acceptance Testing (FAT) and Commissioning of Large Electric Motors

Large electric motors are critical assets across many industries, and their reliability directly impacts safety, productivity, and operational costs. Ensuring these machines are tested, validated, and commissioned properly before entering service is essential to achieving long-term performance and minimizing unexpected failures.

This presentation explores best practices for Factory Acceptance Testing (FAT) and commissioning of large electric motors, with a focus on how Predictive Maintenance (PdM) tools and methodologies can add significant value throughout the process. Key topics include the objectives and scope of FAT, common pitfalls encountered during acceptance testing, and the importance of establishing baseline data prior to installation. Practical examples will be shared to highlight how technologies such as vibration analysis, ultrasound, thermography, and oil analysis can be applied during both FAT and commissioning phases to identify potential defects, verify manufacturer specifications, and ensure optimal machine health from day one.

Drawing on over 25 years of experience in heavy industry and more than a decade in PdM, the session will also examine the role of cross-functional collaboration between vendors, reliability engineers, and end users to drive successful outcomes. By integrating predictive technologies early in the motor lifecycle, organizations can reduce risk, accelerate problem detection, and create a strong foundation for ongoing condition monitoring.Attendees will leave with practical insights into how FAT and commissioning can be strengthened through PdM, as well as strategies to ensure large motors deliver reliability, efficiency, and value throughout their operational life.

Matt Firth, Point Lepreau Nuclear (NB Power)

Matt Firth is a Red Seal Millwright with over 25 years of experience in heavy industry, including more than a decade specializing in predictive maintenance. His career spans multiple sectors such as automotive assembly, pharmaceuticals, steel manufacturing, pulp and paper, and the nuclear industry. Currently, Matt applies his expertise at Point Lepreau Nuclear Power Station in New Brunswick, Canada, where he helps ensure reliability, safety, and performance in a highly critical environment. He also serves as President of the Atlantic Chapter of the Canadian Machinery Vibration Association (CMVA), supporting the growth and development of the predictive maintenance community. Passionate about advancing maintenance practices, Matt holds certifications in Vibration Analysis Category III, Ultrasound Level II, Thermography Level II, MLT I, MLA I, and Motion Amplification Level I. He is committed to sharing knowledge, mentoring others, and driving innovation to strengthen reliability across industries.

Matt Firth est un mécanicien industriel certifié Red Seal avec plus de 25 ans d’expérience dans l’industrie lourde, dont plus d’une décennie spécialisée en maintenance prédictive. Sa carrière couvre plusieurs secteurs, notamment l’assemblage automobile, les produits pharmaceutiques, la fabrication d’acier, les pâtes et papiers, ainsi que l’industrie nucléaire. Actuellement, Matt met son expertise au service de la centrale nucléaire de Point Lepreau, au Nouveau-Brunswick (Canada), où il contribue à assurer la fiabilité, la sécurité et la performance dans un environnement hautement critique. Il est également président de la section Atlantique de l’Association Canadienne en Vibrations de Machines (ACVM), soutenant la croissance et le développement de la communauté de la maintenance prédictive. Passionné par l’amélioration des pratiques de maintenance, Matt détient plusieurs certifications : analyse vibratoire catégorie III, ultrasons niveau II, thermographie niveau II, MLT I, MLA I et amplification de mouvement niveau I. Il est engagé dans le partage des connaissances, le mentorat, et l’innovation afin de renforcer la fiabilité dans l’ensemble des industries.

Structural or mechanical source, what could be the cause?

A client reached out to us after receiving multiple complaints of a vibrating stairs set that happened to be one that most employes of that department would go by every day. As their mill was old and had major corrosion issues, management was keen to address this safety risk. The requests felt into the structural department to investigate the matter. As vibration was the source of the complaint, they were not equipped to deal with the problem. As they knew about motion magnification technology, we were asked to help finding the solution to their problem. Using various techniques such as motion magnification videos, bump test, advanced vibration monitoring, we were able to narrow down the culprit. This is a reminder that whenever a client points you to a specific direction, better off starting with a fresh mind and investigate all possibilities. If not, you can run around and be left with no real answer.

Structurelle ou mécanique, que pourrait bien être la cause du problème ?

Un client nous a contacté après avoir reçu plusieurs plaintes au sujet de fortes vibrations ressenties lors de l’utilisation d’un escalier. Il se trouve que cet escalier est celui qui est emprunté par la majorité des employés du secteur et ce, plusieurs fois par jour. Comme l’usine est âgée et aux proies de problème de corrosion, la direction n’a pas hésité à adresser la problématique. La requête est tombée au sein du département interne de structure de l’usine. Comme la problématique provenait de vibration, le groupe n’était pas outillé pour investiguer le problème. Connaissant l’existence de la technologie d’amplification de mouvement, ils ont fait appel a notre équipe pour trouver la source de cette vibration. En utilisant différente techniques comme les vidéos d’amplification de mouvement, tests d’impact ainsi que des tests de vibration avancés, nous avons réussi à trouver la cause du problème. Ceci est un rappel que lorsqu’un client pointe dans une direction concernant la source d’un problème, qu’il est préférable de commencer à neuf et de se faire ses propres idées. Investiguer toutes les possibilités est la clé sans quoi, il est possible de tourner en rond indéfiniment.

Hugo Racine, Contrôles Laurentide

Hugo Racine has been a vibration specialist at Contrôles Laurentide since early 2017. Over the years, he has worked in various industrial sectors and has been exposed to a variety of issues. This has allowed him to help his clients thrive in their operations. He holds various roles within the Laurentide group, including vibration program start-up and audit, and lead trainer. Digging into the root causes of complex problems using today’s methods and technologies is his favorite part of his job.

Hugo Racine occupe le poste de spécialiste en vibration au sein de l’entreprise Contrôles Laurentide depuis le début de 2017. Au fil des années, il travaillé dans divers secteurs industriels et a été exposé à une variété de problèmes. Cela lui a permis d’aider ses clients à prospérer dans leurs opérations. Il occupe différents rôles au sein du groupe Laurentide : démarrage et audit de programmes vibratoires et formateur principal. Creuser la cause de problèmes complexes en utilisant des méthodes et technologies d’aujourd’hui est ce qu’il préfère dans son travail.

Un peu de préparation, beaucoup d’efficacité : comment des bonnes pratiques de maintenance peuvent sauver nos techniciens en situation d’alignement et d’équilibrage

La maintenance de précision est souvent vue comme un moyen d’augmenter la durée de vie des machines. Mais c’est aussi un atout majeur pour nos équipes de techniciens, qui peuvent ainsi optimiser leur temps et leur énergie. Dans cette présentation, nous allons vous montrer à travers des cas concrets comment de bonnes pratiques d’alignement et d’équilibrage peuvent transformer une intervention frustrante et inefficace en une opération rapide et réussie. Nous explorerons deux scénarios réels où l’empressement a causé d’importantes pertes de temps. Le premier cas portera sur les pièges courants de l’alignement et démontrera comment un manque de vérification initiale a mené à des heures de travail gaspillées, alors que quelques minutes de préparation auraient suffi à régler le problème. Le second cas traitera de l’équilibrage d’un ventilateur, pour illustrer comment une simple inspection préalable aurait pu éviter de nombreuses tentatives infructueuses dues à des conditions instables. En conclusion, nous synthétiserons ces leçons en présentant les règles d’or d’une maintenance efficace : toujours préparer avant d’agir, s’assurer de l’état optimal de la machine en amont et utiliser l’analyse vibratoire pour diagnostiquer et valider chaque intervention. L’objectif ultime est de nous permettre de travailler plus intelligemment, et de rendre notre travail plus gratifiant.

David Lévesque, Viabilité

Fort d’une solide expérience dans le domaine de la maintenance prédictive, David Lévesque est un professionnel spécialisé en analyse de vibration (Catégorie III) et en Ultrason (Niveau II). Après avoir obtenu son diplôme de technicien en génie électrique, il a acquis une expérience variée en automatisation de bâtiments et en gestion d’entreprise. En poste chez Viabilité depuis 13 ans, David se concentre sur l’implantation de programmes de maintenance prédictive. Son approche est particulièrement rigoureuse dans la mise en œuvre de routes de vibration et de graissage à l’ultrason. Il contribue également en rédigeant des rapports de bris pour aider à mieux comprendre et prévenir les défaillances. Après avoir été impliqué au sein de l’ACVM Québec comme directeur des ressources d’accueil, il est aujourd’hui le président de ce chapitre.

With solid experience in the field of predictive maintenance, David Lévesque is a professional specializing in Vibration Analysis (Category III) and Ultrasound (Level II). After graduating as an electrical engineering technician, he gained varied experience in building automation and business management. Working with Viability for 13 years, David focuses on the implementation of predictive maintenance programs. His approach is particularly rigorous in setting up vibration and ultrasound greasing routes. He also contributes by writing failure reports to help better understand and prevent breakdowns. After being involved with the ACVM Quebec as director of greeting resources, he is now the president of this chapter.

Frottement dans les paliers lisses

Dans cette présentation, nous fournirons :

-

- Définition du frottement;

- La vibration générée par ces frottements;

- Les forces générées par le frottement et le changement de raideur;

- Description des changements du comportement dynamique des rotors résultants du frottement;

- Vibration spirale (Effet Morton).

Kamel Bouazza-Abid, Delom Services (Wajax Group)

Kamel Bouazza-Abid, né en 1982 à Témouchent (Algérie), est un spécialiste en fiabilité reconnu pour son expertise en diagnostic des machines et en analyse de vibrations. Après avoir obtenu son baccalauréat en génie mécanique en 2006, Sa carrière en vibration prend son envol carrière en 2011 à la centrale thermique de cogénération 1200 MW en Algérie, en tant qu’ingénieur diagnostic machines. En 2017, il s’installe au Canada avec sa famille et poursuit sa formation avec une AEC en génie mécanique, obtenue en 2018. Il enchaîne ensuite des postes de technicien en fiabilité chez Contrôles Laurentides, puis d’inspecteur en maintenance chez Lafarge Holcim. Aujourd’hui, il travaille chez Delom Service (Wajax) comme spécialiste en fiabilité et est CPI (candidat à la profession d’ingénieur). Certifié en analyse de vibrations (CAT III), il se spécialise également en tests de résonance et mise en service d’équipements rotatifs, combinant l’expertise technique et passion pour l’excellence opérationnelle.

Kamel Bouazza-Abid, born in 1982 in Témouchent, Algeria, is a reliability specialist recognized for his expertise in machine diagnostics and vibration analysis. After earning his high school diploma in mechanical engineering in 2006, he began his career in 2011 at a 1200 MW cogeneration power plant in Algeria as a machine diagnostics engineer. In 2017, he moved to Canada with his family and completed an Attestation of Collegial Studies (AEC) in mechanical engineering in 2018. He then worked as a reliability technician at Contrôles Laurentides, followed by a maintenance inspector role at Lafarge Holcim. Today, he holds the position of Reliability Specialist at Delom Service (Wajax) and is a Candidate to the Engineering Profession (CPI). Certified in vibration analysis (CAT III), he specializes in resonance testing, machine diagnostics, and commissioning of rotating equipment—bringing together deep technical knowledge and a commitment to operational excellence.

Advantages of Monitoring Oil with a New Generation of Sensor

Lubricants are the lifeblood of industrial machinery, and their condition mirrors the overall health of critical assets. Traditional laboratory oil analysis remains valuable, yet it is constrained by delays in sampling, transportation, and processing. A new generation of online oil monitoring sensors eliminates these limitations by providing real-time, continuous insight into contamination, wear, and lubricant degradation — enabling maintenance teams to move from reactive to predictive strategies.

Solid particle contamination — often accompanied by water, fuel, or soot ingress — is responsible for the majority of wear-related failures in lubricated machinery. Even microscopic debris can accelerate additive depletion, increase viscosity, and initiate premature component damage.

Modern digital sensors equipped with optical imaging and multi-parameter measurement go beyond simple particle counting: they identify particle size, shape, and type, while simultaneously tracking viscosity, water content, density, and temperature. This level of detail allows maintenance professionals to pinpoint the root cause of degradation — whether from wear, dirt ingress, or lubricant oxidation. When integrated into a predictive maintenance platform, these intelligent sensors create a continuous contamination and condition trend, allowing early detection of abnormal wear mechanisms and more efficient planning of service interventions. The result is a measurable reduction in downtime, lower oil consumption, and extended component life.

By transforming oil into a dynamic diagnostic medium, this new generation of sensors redefines lubrication management. Facilities gain faster decision-making, improved asset reliability, and a clearer understanding of their machines’ health. In essence, online oil monitoring technology turns maintenance from an after-the-fact response into a data-driven process that safeguards productivity, optimizes resources, and ensures sustainable performance.

Charles Gagné, STCD

Charles Gagné is a Product Specialist at STCD Inc. with over 15 years of experience in predictive maintenance. Certified as a Category III vibration analyst since 2016, he has delivered numerous Category I and II training sessions and supported the implementation of vibration analysis programs across multiple industries. His expertise lies in online condition monitoring systems and integration, helping organizations transition toward data-driven reliability and proactive maintenance strategies.

Charles Gagné est spécialiste de produits chez STCD Inc. et possède plus de 15 ans d’expérience en maintenance prédictive. Certifié analyste en vibrations de catégorie III depuis 2016, il a animé de nombreuses formations de catégories I et II et soutenu la mise en œuvre de programmes d’analyse vibratoire dans de nombreux secteurs d’activité. Son expertise réside dans les systèmes de surveillance d’état en ligne et leur intégration, aidant les organisations à opérer une transition vers une fiabilité axée sur les données et des stratégies de maintenance proactive.

Response Screening of Structural Systems

Industry and municipalities are faced with the rising cost of infrastructure maintenance. Asset management professions continue to push for non-destructive assessment of the associated static and dynamic assets. Impact testing (Frequency Response Function or FRF) determines system natural frequency impacting static and dynamic (at rest) assets with a hammer or large mass (instrumented with a force sensor) and assessing the sensor (accelerometer) response (natural frequencies, phase shift and coherence). This paper discusses a risk-based screening methodology for large static systems of similar components of similar configuration. Using Impact testing of static assets of similar configuration and analysing the population of the response parameters, one can identify outliers for further inspection. The paper will also provide some methodology for severity ranking to better under the risks.

Matthew Holmes, Acuren

Matthew Holmes is a Category III vibration specialist (CMVA and VI) and professional engineer (NS) with 28 years of experience in asset management and diagnostics for multiple industry segments (including power generation, manufacturing, marine vessels, aerospace, military weapons systems). Matthew is currently the Division Manager – Reliability with Acuren supporting Acuren’s throughout North America. Mr. Holmes has served on the CMVA national Board of Directors since 2015, held the position of Vice President from 2017 to 2019 and as President from 2019 to 2024. Mr. Holmes currently serves on the CMVA ISO Committee.

Matthew Holmes est spécialiste des vibrations de catégorie III (ACVM et VI) et ingénieur professionnel (NS). Il possède 28 ans d’expérience en gestion et diagnostic d’actifs pour de nombreux secteurs d’activité (production d’énergie, fabrication, navires, aérospatiale et systèmes d’armes militaires). Il est actuellement chef de division Fiabilité chez Acuren, où il accompagne les activités d’Acuren en Amérique du Nord. M. Holmes siège au conseil d’administration national de l’ACVM depuis 2015, dont il a été vice-président de 2017 à 2019 et président de 2019 à 2024. Il siège actuellement au comité ISO de l’ACVM.

Identifying and Addressing Background Vibration Signals in CBM & Advanced Diagnostics

Many vibration testing methods are affected by background sources. Motion amplification cameras, proximity probes, impact testing (‘bump’ testing for resonance or natural frequency determination), and most other vibration measurements are subject to background vibration. If not identified and addressed during testing amplitudes may appear higher than actual and incorrect recommendations be produced as a result. Types of measurements commonly influenced by background vibration readings include video vibration analysis (motion amplification), displacement measurements recorded by proximity probes, and readings from accelerometers or velometers. This presentation will discuss how to identify common background vibration sources and methods to reduce the influence and likelihood of background vibration influencing results and recommendations for routine CBM analysis as well as more advanced testing.

Dora Orchard, Acuren

Dora Orchard is a CAT III vibration analyst with the CMVA and VI and professional engineer in New Brunswick with over 30 years of experience in maintenance and reliability. She is a Senior Reliability Engineer with Acuren, supporting maintenance, reliability, and operations in a variety of industrial sectors (pulp and paper, mineral processing, manufacturing, energy, transportation and defence). Since joining the company in 2001, she has been involved in numerous vibration monitoring and analysis projects for clients in these and other industries. Specific responsibilities and projects have included reliability program development and assessment, asset criticality assessment, directing and performing advanced equipment vibration diagnostics and troubleshooting. This includes development and implementation of corrective action plans, including vibration control and dynamic balancing and other condition monitoring technologies. Working closely with the Acuren Team, she has participated in the development and delivery of various specialized techniques, including IN-SITU™ Roll Balancing and SCORE™ Maintenance Assessment.

Dora Orchard est analyste en vibrations de niveau CAT III certifiée par l’ACVM et le VI, ainsi qu’ingénieure professionnelle au Nouveau-Brunswick, avec plus de 30 ans d’expérience en maintenance et fiabilité. Elle est ingénieure principale en fiabilité chez Acuren, où elle soutient les activités de maintenance, de fiabilité et d’exploitation dans divers secteurs industriels (pâtes et papiers, traitement des minéraux, fabrication, énergie, transport et défense). Depuis son arrivée dans l’entreprise en 2001, elle a participé à de nombreux projets de surveillance et d’analyse des vibrations pour des clients de ces industries et d’autres domaines. Ses responsabilités et projets spécifiques ont inclus le développement et l’évaluation de programmes de fiabilité, l’évaluation de la criticité des actifs, ainsi que la direction et la réalisation de diagnostics avancés et de dépannages d’équipements basés sur les vibrations. Cela comprend également le développement et la mise en œuvre de plans d’action corrective, incluant le contrôle des vibrations, l’équilibrage dynamique, et l’utilisation d’autres technologies de surveillance de l’état. En collaboration étroite avec l’équipe d’Acuren, elle a participé au développement et à la mise en œuvre de diverses techniques spécialisées, telles que l’équilibrage de rouleaux IN-SITU™ et l’évaluation de maintenance SCORE™.